We had a customer who produced the composite metal products. In order to enable customers to purchase the right CNC metal spinning machine . We got the drawing from customer. The spun products were very simple, just for spun products necking. So we recommended the model SP600 according to the drawing. After that, we signed the contact and got the down payment from them. When we plan to arrange the machine production, they inform us that drawing just is the part of full drawing suddenly. Due to the drawing is confidential document, so they just send part of full drawing to us.

We were very surprised when we got the full drawing from the customer. The thickness of material is very thick. The model SP600 is not capable to spin it. So if your drawings are confidential and cannot be made public, your data is not convenient to tell. Please read our options as below:

1. Ask yourself the simplest questions

2. Machine Type

3. Diameter and Height of metal spun products

4. Thickness of blank plate material

5. Material of spun products

6. Inquiry to the supplier

7. Sample Confirmation

1.Ask yourself the simplest questions:

LETIPTOP CNC Spinning Machine is universal metal spinning machine that can easily perform spinning, necking, flow forming and so on. When you need a new metal spinning machine, you should know the technical information as belw:

●What is the material of spun products?

●The diameter of spun products?

●Max. length/height of spun products?

●The thickness of spun products?

Record your answers and let us start selecting the machine.

2.Machine Type

If the wall thickness is thin and the diameter is small, the light-duty CNC metal spinning machine is the best choice. It can save 30%-40% of the production cost. The other advantage is that the feed speed of the tool holder of light-duty metal spinning machine is faster than that heavy-duty metal spinning machine. It can improve the production efficiency greatly.

Conversely, if the wall thickness is thicker and the diameter is large, you can choose the heavy-duty metal spinning machine. Because if you choose light-duty metal spinning machine at this time, it will result in

1.The defect rate of spun products is very high due to the rigidity and stability of the machine is not enough. The production efficiency is lower.

2.Machine overload working will wear the machine. It will make the machine lift shorter.

Therefore, we recommended buying heavy-duty metal spinning machine at this time.d

3.Diameter and Height of metal spun products

If the spun product diameter is more than 1m and the weight is heavy, it usually needs two people or use the crane to load the blank plate material. The customer should consider whether it is convenient for lifting the blank plate material. If the machine design is not suitable for lifting the blank plate material, it will affect the production output. If the height of the spun product exceeds 400mm, it is necessary to consider whether there is enough space for demoulding between the spindle and the the tailstock pushing pad.

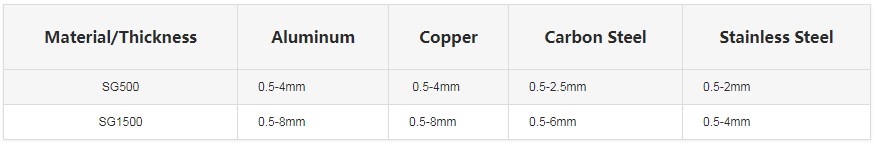

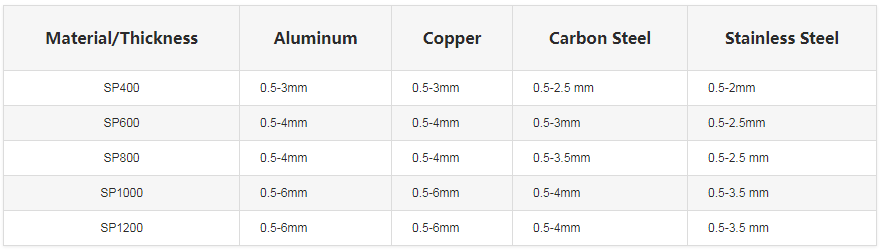

4.Thickness of blank plate material

The general spinning materials are: aluminum, aluminum alloy, copper, brass, carbon steel, cold rolled steel, stainless steel and silver. You can select the machine model according to the thickness of the material. The tolerance range is: ±0.1mm-0.2mm

5.Material of spun products

If you process stainless steel, you can select heavy-duty metal spinning machine. Due to the hardness and toughness of stainless steel is high, the request to the machine rigidity and stability is also high, So the strong performance of the heavy-duty metal spinning machine can provide better control to the resilience and precision of stainless steel.

If you process aluminum, aluminum alloy, copper, brass, carbon steel, cold rolled steel spun products, you can select light-duty metal spinning machine. The tool holder feeds at a high speed and can improve work efficiency.

6.Inquiry to the supplier

If you are willing to share your detailed metal spun products drawing with us, LETIPTOP will recommend the appropriate cnc spin forming machine model and give you detailed spinning scheme for your spun products.

We will program by CNC controller according to your drawing and making the processing easier in one step. If your company has any new spun products need to be made in the future, we will assist in programming with free charges. One service, benefiting for life.

7.Sample Confirmation

If you have no way to confirm that which sheet metal cnc spinning machine model can be processed your spun products very well, we can make the samples for you to check.

1.You can send the sample of metal spun parts to us by express company, So that we can measure it after we receive it, and then we can make the samples for you.

2.You can send the drawing to us, then we can make the samples accordingly.

We sincerely welcome to visit our factory for on-site inspection, so that you can observe the details better for sample making.