Difficulties and solutions for Milk bucket CNC metal spinning

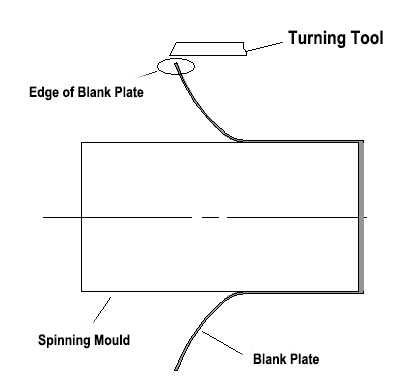

The processing technology of the Milk bucket is spinning or drawing the blank sheet to straight barrel, and then necking the milk pail. If the first process is formed by metal spinning, the edge of milk pail will be irregularity due to the height of the milk pail and spinning paths. In this case, the turning tool is required to cut the edge to prevent wrinkling and spinning cracking.

The tooling fixture is the most important when spinning and necking the bucket. If the clamping force is not enough, the product will be slipped and scratched. If the clamping force is too large, the product will be deformed. If the clamping force is uneven, the necking will be wrinkled. In addition, the height of the bucket is generally high. So it is necessary to consider whether the stroke of the equipment is sufficient to demould.