Metal Spinning introduction:

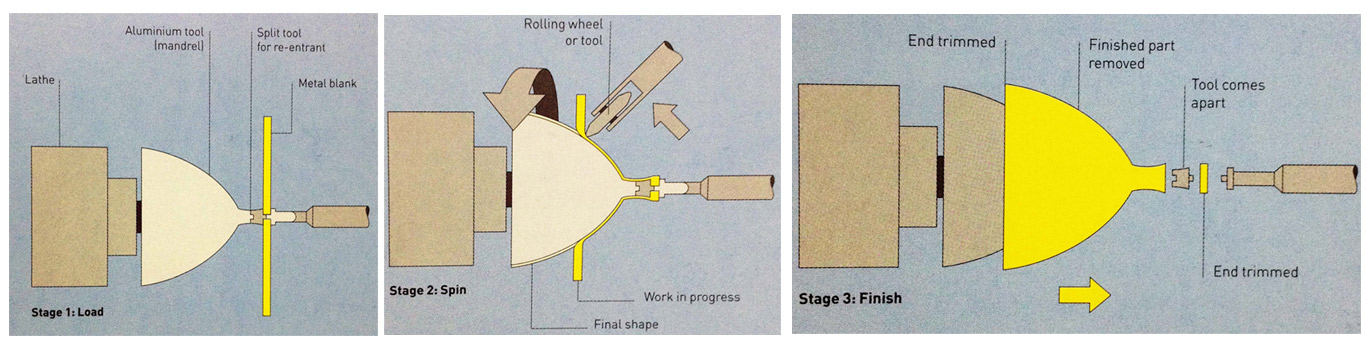

Metal Spinning is to fix the flat plate or hollow blank on the mold of the spinning machine, then press it by the spinning rollers to make local deformation when spindle working. Under the joint action of the feeding motion and spinning rollers, the local deformation is gradually extended to the entire surface of the blank and resting against the mold to complete the spinning process.

Metal Spinning is a special forming method. The deep drawing, flanging, necking, bulging and crimping processes of various shapes can be performed by the metal spinning method.

According to the deformation principle, metal spinning machine divided into:

Ordinary Spinning Machine

Powerful Spinning Machine

According to the spindle position, it is divided into:

Horizontal Spinning Machine

Vertical Spinning Machine

According to the number of spinner roller, it is divided into:

Single-roller Spinning Machine

Double-roller Spinning Machine

Multi-roller Spinning Machine

According to the relative position of the moulds, it is divided into:

External Spinning Machine

Internal Spinning Machine

According to the direction of metal flow, it is divided into:

Positive rotation Spinning Machine

Reverse rotation Spinning Machine

Positive and negative rotation Spinning Machine